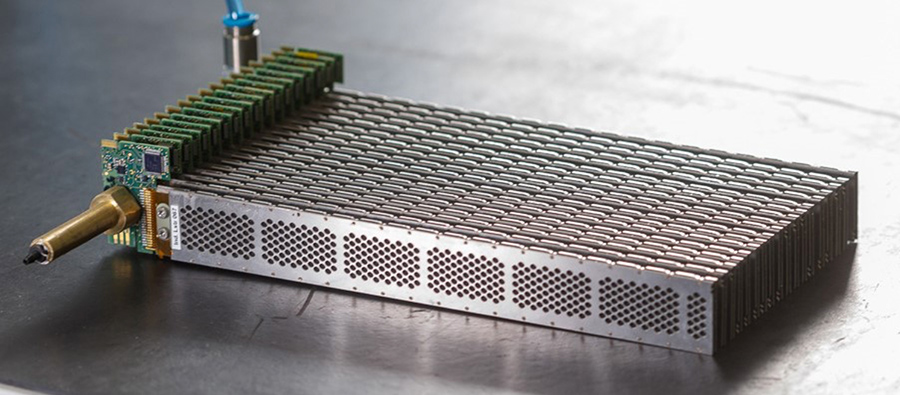

Lamina® micro fuel cell has a laminated design which gives it unique properties

The micro fuel cell Lamina® has a patented laminated design that gives it unique properties: It is thin, light and modular, scalable and flexible. Therefore, it can be easily mounted in limited spaces where traditional stacked fuel cells cannot fit. At the same time, Lamina delivers the highest possible energy density per volume and surface area.

CUSTOMER CUSTOMIZATION

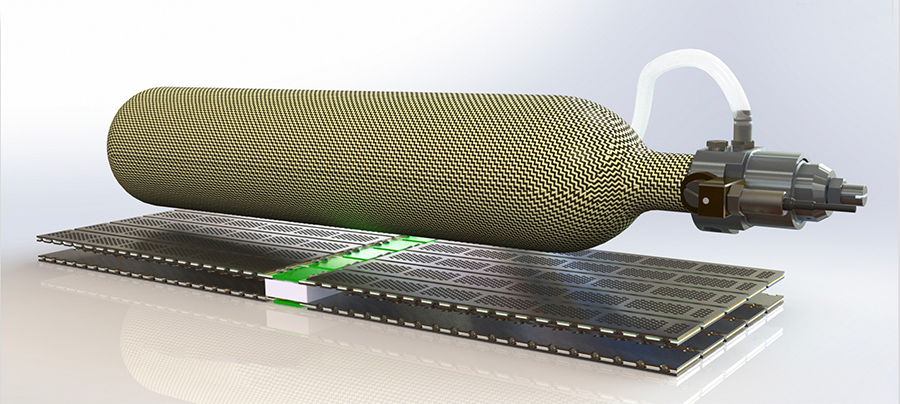

Lamina’s® standard box has room for 24 Lamina® modules, which together generate 240 W, a

suitable power for logistics robots and e-bikes. At the same time, the Lamina architecture is

scalable and therefore the customer can get any desired power, for example seven modules in one box (70 W) or ten interconnected boxes (2,400 W).

HYBRID SOLUTIONS

Lamina® can be combined with accumulators, e.g. batteries, in hybrid solutions that create a reliable energy and power system. It is a combination that enables high electrical performance and optimizes the lifetime of the accumulators.

An assembled Lamina® with 24 modules provides an output of 240 W.

The Lamina® technology's measurable benefits compared to traditional fuel cells

Lamina® fuel cells are not only lighter, more compact and therefore more flexible than traditional stacked fuel cells. Above all, they are more cost-effective. Expressed in numbers:

premises space is also reduced.

Planar Lamina Solution allows packaging in small areas.

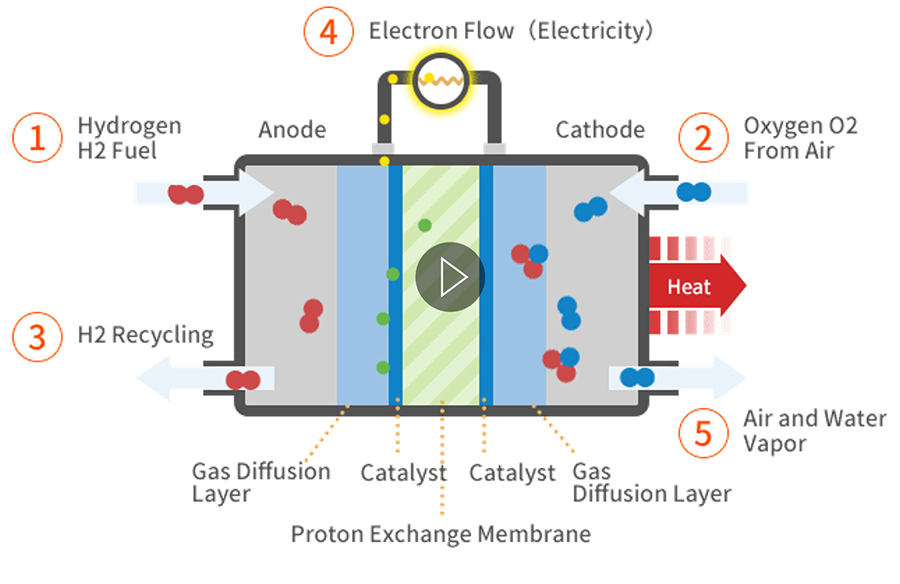

The differences between a fuel cell and a regular battery

harmony.

The image shows the physical principles of a fuel cell.

The differences between the Lamina® technology and traditional stacked fuel cells

Please scroll table below to the left to see all content.

| FCT FUEL CELL SYSTEM | Versus | CONVENTIONAL FUEL CELL STACK |

|---|---|---|

| Active or passive air feed | versus | Active feed only, large support systems required |

| Applicable in a wide range of solution, from 10W – 3,000W | versus | Aimed at large applications (>3,000W) |

| Open end solution, operates at ambient pressure | versus | Close end solution, operates at very high pressure |

| Flexible in shape and form | versus | Monolithic, cannot be designed to available space |

| Thin, modular, scalable | versus | Rigid systems, not easily configurable |

| Does not use bipolar plates; cheaper to manufacture | versus | Significant production costs |